Your vehicle's transmission is a critical component that ensures smooth operation and optimal performance. When it begins to fail, addressing the issue promptly can save you significant time, money, and stress. At Circle D Transmission, we know that understanding the early signs of transmission problems can empower vehicle owners to take proactive action before more extensive damage occurs.

Here, we’ll guide you through the key indicators that your transmission may need a rebuild, what to watch out for, and how to respond effectively.

1. Warning Signs from Your Transmission

The first step in diagnosing transmission trouble is recognizing the early warning signs. Transmission systems are sophisticated and designed to signal when something is wrong. Pay attention to these red flags:

- Difficulty Shifting Gears. If you notice your vehicle hesitating, slipping out of gear, or struggling to shift smoothly, this could indicate damage to your transmission’s internal components. Whether you’re driving an automatic or manual vehicle, delayed engagement or unexpected shifts shouldn’t be ignored.

- Unusual Noises. A well-functioning transmission operates quietly. Sounds such as grinding, whining, or buzzing could point to worn-out gears, internal damage, or insufficient transmission fluid. These noises often grow louder over time, so catching them early is essential.

- Fluid Leaks. Transmission fluid is vital for lubrication and heat control. If you spot red or pink fluid puddling under your car, this leak could indicate a serious issue with seals or lines. Low fluid levels often lead to overheating, increasing wear and tear.

Listening to your vehicle and observing any performance changes are crucial first steps in diagnosing transmission problems.

2. Diagnosing Performance Issues

Beyond obvious signs, performance changes can also hint at a failing transmission. Keeping an eye on your vehicle’s behavior can help pinpoint deeper issues.

- Overheating Transmission. An overheating transmission often results from insufficient fluid levels or clogged cooling lines. You might detect a burning smell, which is a clear indicator that your system is running too hot. Overheated systems often degrade quickly, requiring a rebuild to restore function.

- Slipping Gears. If your transmission unexpectedly shifts in and out of gear while driving, that’s a serious warning sign. Gear slippage can jeopardize your safety, as it hampers your ability to maintain control on the road. This issue can arise from worn clutches or damaged bands within the system.

- Check Engine Light. Modern vehicles are equipped with sensors to monitor transmission health. If your check engine light is on, it could mean the system has detected irregularities in your transmission, such as increased friction or incorrect fluid pressure. A diagnostic scan at this stage can uncover specific fault codes to identify the problem.

By catching performance issues early, you can prevent them from escalating into full-blown transmission failure.

3. Regular Maintenance Helps Avoid Emergencies

One of the most effective ways to avoid extensive transmission rebuilds is regular maintenance. Keeping up with servicing your vehicle can help you catch minor issues before they evolve into major problems.

- Routine Fluid Checks and Changes. Transmission fluid degrades over time, losing its lubricating and cooling properties. Replacing the fluid at the intervals recommended by your vehicle manufacturer can protect your transmission from wear and overheating. Be sure to use the right type of fluid, as specified in your owner’s manual.

- Professional Inspections. Licensed technicians have the tools and expertise to identify potential transmission problems early. Annual inspections can uncover worn parts, small leaks, or calibration issues before they lead to a breakdown.

- Stay Alert. Make it part of your driving habits to pay attention to changes in your vehicle’s performance. Early detection, combined with quick action, is often the difference between a simple repair and a full transmission rebuild.

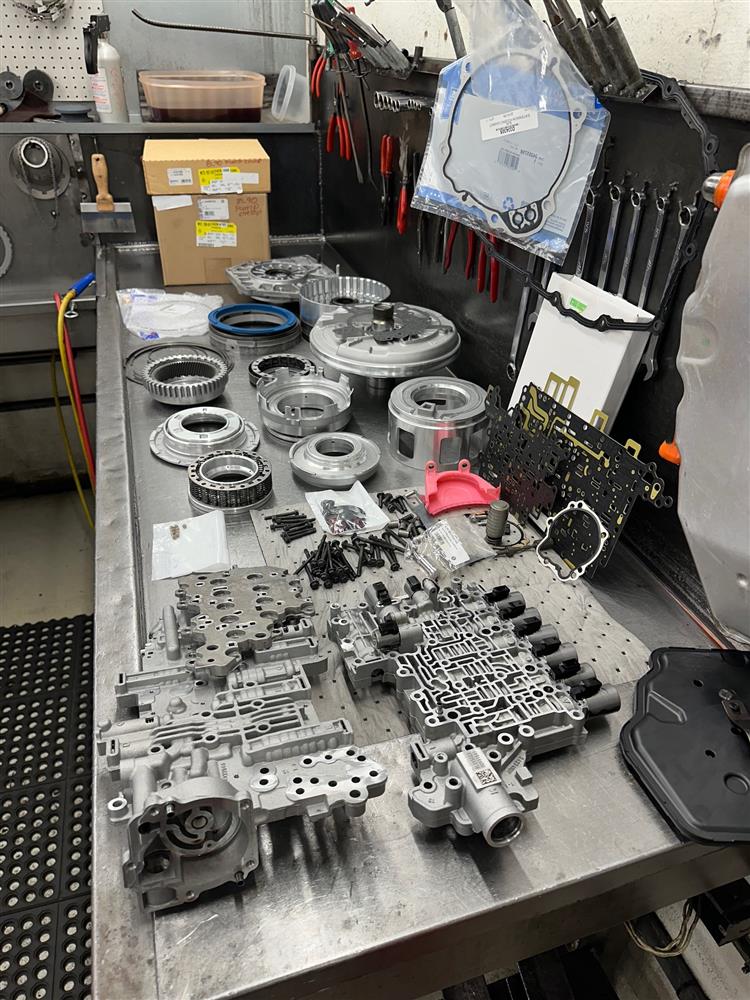

When issues do arise, our team at Circle D Transmission specializes in 6L80 transmission rebuilds designed to enhance your vehicle’s performance and reliability.

Frequently Asked Questions

What is the average lifespan of a 6L80 transmission before it needs a rebuild?

The 6L80 transmission is known for its durability and can last between 150,000 to 200,000 miles with proper maintenance. However, heavy towing, frequent stop-and-go traffic, or neglecting fluid changes can shorten its lifespan, making a rebuild necessary sooner.

How do I know if a 6L80 transmission rebuild is the right solution?

A rebuild may be required if your transmission shows signs of slipping gears, delayed engagement, persistent overheating, or frequent fluid leaks. Rebuilding involves replacing worn-out components with high-quality parts, restoring the transmission’s performance without the cost of a full replacement. Consult a trusted professional to assess your specific transmission condition.

Addressing transmission concerns swiftly can save you from costly repairs and unexpected breakdowns. At Circle D Transmission, we aim to provide transparent guidance and top-quality service tailored to your needs. If you suspect your vehicle’s transmission is failing, don’t hesitate to contact us. Our experienced technicians are here to provide diagnostics, expert advice, and industry-leading rebuild services to keep you on the road.